OXFORD Xplore EDS Detector is the next generation of EDS detector for routine analysis in the SEM. This advanced detector is available in 15mm² and 30mm² sensor sizes, designed for a wide range of applications. Utilizing new technology from the larger Ultim Max detectors, Xplore offers rapid data collection for live EDS analysis, while still guaranteeing the automatic and reliable results required for routine analysis applications.

The Xplore EDS Detector is the next generation of EDS detector for routine analysis in the SEM. The detector is available in 15mm² and 30mm² sensor sizes and is designed for a wide range of applications. Xplore uses much of the new technology introduced and showcased in our larger Ultim Max detectors. It offers rapid data collection for live EDS analysis, while still guaranteeing the automatic reliable results required for routine analysis applications.

Features of Oxford Xplore EDS Detector

Speed

- The combination of Extreme electronics with the X1 pulse processor allows Xplore to map samples at count rates of 1,000,000 cps and accurately quantify composition at 100,000 cps

Sensitivity

- New compact design offers a small footprint and unique capability for

in-field repair for maximum up-time and minimum service requirement

Extreme Electronics

- Xplore incorporates tried and tested Extreme Electronics, which provides the lowest noise signal detection and processing. They ensure excellent energy resolution and spectrum quality is achieved at high count rates, enabling a guarantee of 129eV Mn Kα resolution at 100,000 cps

The Xplore EDS Detector combines advanced technology and reliable performance, making it an essential tool for efficient and accurate SEM analysis. Its versatility and rapid data collection capabilities ensure that users can achieve precise and dependable results across a variety of applications.

Ideal for ‘Quality Control’ applications

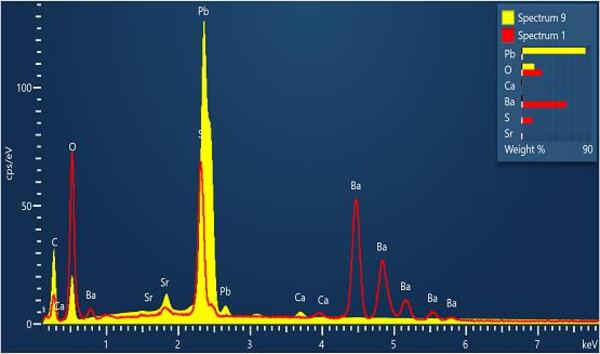

Quickly spot any differences between a production sample and a control sample with instant Live spectrum compare.

Identification of counterfeit or patent-infringing products

AZtecLive software can help users easily see key element distribution and chemistry differences or similarities between branded products and suspected counterfeits.

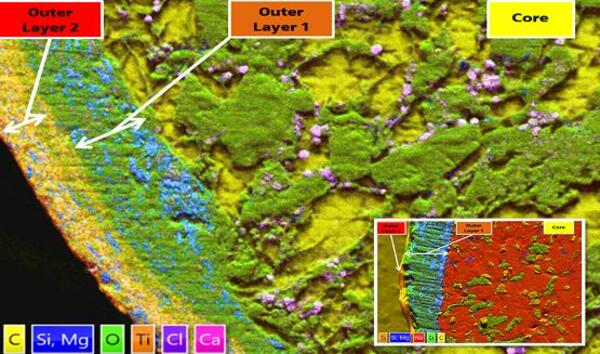

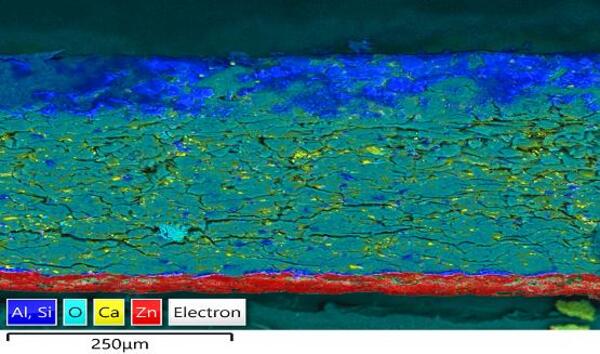

Layer and composites

Paper manufacturers use additives and coatings to give their products different properties. For example, calcium carbonate is used to reduce paper shrinkage and improve whiteness. Preparing cross-section of your sample is a great way of investigating their structure, X-ray maps overlaid on an electron image distinguish layers, coatings and additive distributions.