To achieve Vanilla pods with characteristic flavor, mastering temperature and humidity changes during the curing process is crucial. The KSON Vanilla Curing Chamber provides professional temperature and humidity control capabilities, simulating and generating natural curing conditions for Vanilla pods. This chamber ensures that the curing process remains unaffected by climate, making it easier for craftsmen to produce world-class, high-quality Vanilla pods and their flavor.

Features of KSON Vanilla Curing Chamber

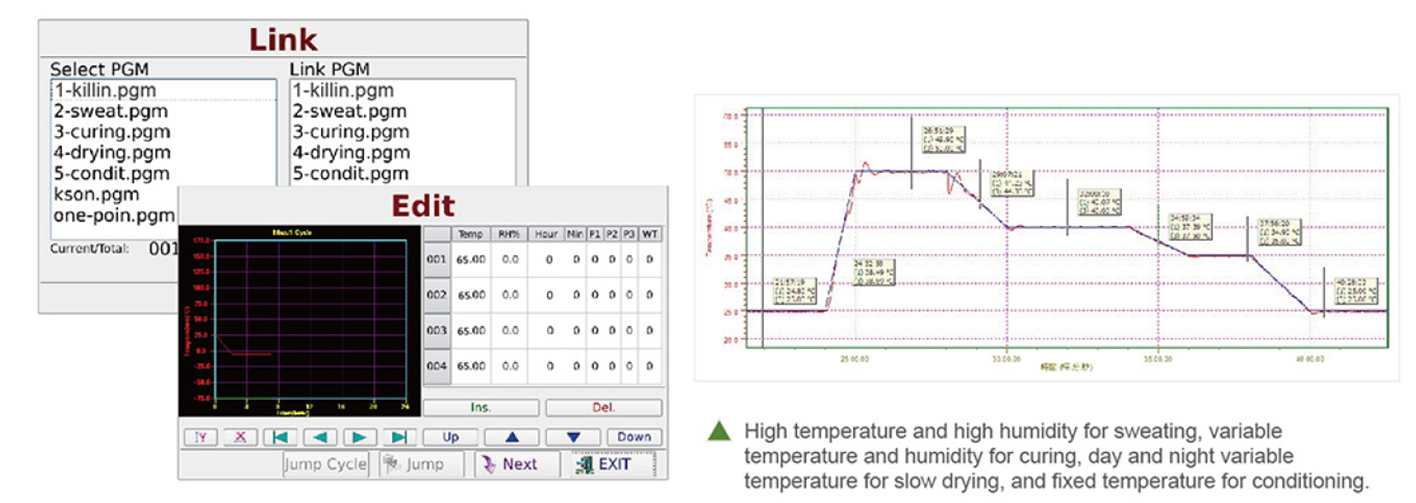

Professional Temperature and Humidity Control

- The KSON Vanilla Curing Chamber simulates natural curing conditions with convection heated air for Killing, precise constant temperature for Sweating & Fermentation, variable temperature to remove humidity (dehumidify) for Curing processing, day and night variable temperature for slow Drying, and constant temperature for Conditioning and Ripening. This ensures optimal curing conditions regardless of external climate factors.

User-Friendly Design

- The chamber is designed to be a computer, workstation web-based application, and mobile APP-oriented cloud-based RD collaboration platform and solution. This makes it easy for users to monitor and control the curing process in real-time, ensuring consistent results.

Climate Independence

- By performing the curing process in the KSON Vanilla Curing Chamber, users can avoid worries and impacts from rainy days, rainy seasons, and monsoons. This eliminates climate-related issues such as excessive humidity, mold, and low temperatures, ensuring high-quality cured Vanilla pods.

Comprehensive Curing Stages

- The chamber supports the five stages of curing processing for Vanilla pods – Killing, Sweating, Curing, Drying, and Conditioning. Each stage can be completed by one person, making the process efficient and manageable.

The KSON Vanilla Curing Chamber is an essential tool for craftsmen aiming to produce high-quality Vanilla pods with consistent flavor. Its advanced temperature and humidity control capabilities, user-friendly design, and climate independence make it a reliable solution for the curing process. By utilizing this chamber, users can ensure optimal curing conditions and achieve world-class results, free from the worries of climate-related issues.

Application features:

1. Five built-in vanilla pod sweating, fermentation program modes (Standard feature) for curing processing vanilla pods.

2. A record of monitoring the temperature inside the pods throughout the process (Standard feature). Monitoring the curing processing status by easily access KSON APP in real time (with Wi-Fi).

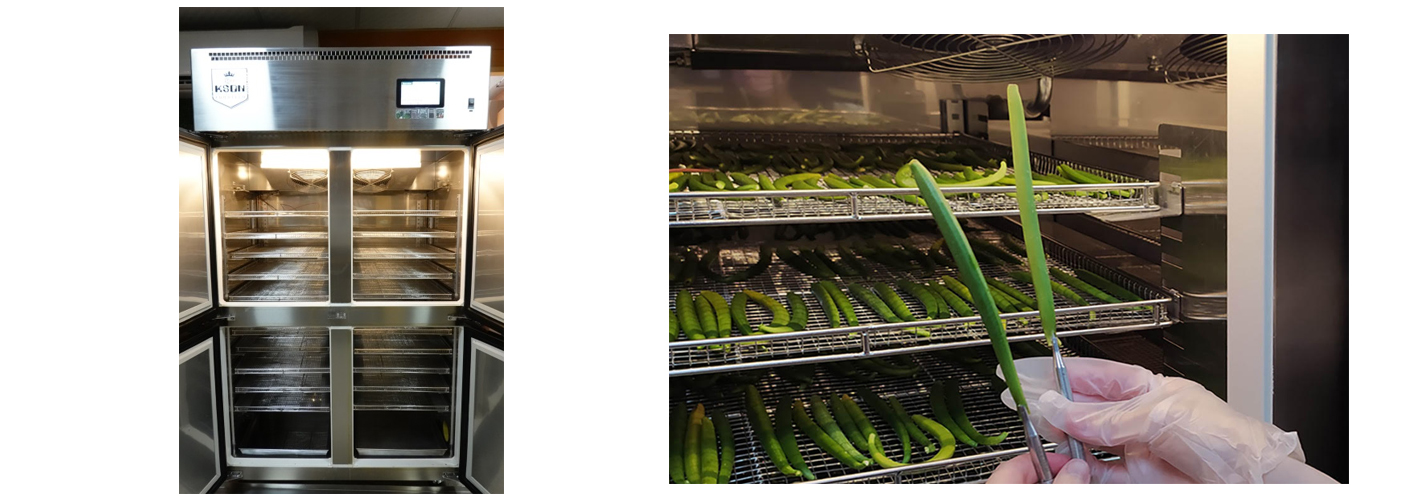

3. It has 2 columns with 10 layer of mesh trays each for vanilla pods curing processing (convenient, fast and handy to do). It has incorporated an illumination lighting for user to view vanilla pods curing processing status on the mesh trays.

4. The chamber is also available for other food fermentation application such as Kombucha, Cocoa, Yogurt, Coffee beans anaerobic, Saccharomyces fermentation.